310 Green Glide Triangle, 5/16" Gap

The 310 Green Glide Triangle is designed mount wall panels with prefabricated furring. The 310 Green Glide Triangle is a companion clip to the 300 Green Glide and is especially designed to allow for installations of pre-assembled corner panels and returns. The 310 Green Glide Triangle and the 300 Green Glide can be used together. The 300 Green Glide has a straight-in lock down connection while the 310 Green Glide Triangle may be connected in a sideways motion before being locked in place with a downward motion.

Read more ↓

- Product Description

- Introduction Animation

- Installation Guides

- Demonstration Videos

- Drawings & Models

- Product Specifications

Application

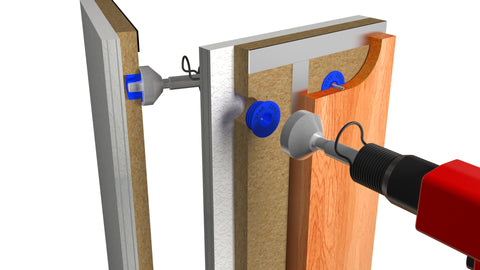

The 310 Green Glide Triangle is designed mount wall panels with prefabricated furring. The 310 Green Glide Triangle is a companion clip to the 300 Green Glide and is especially designed to allow for installations of pre-assembled corner panels and returns. The 310 Green Glide Triangle and the 300 Green Glide can be used together. The 300 Green Glide has a straight-in lock down connection while the 310 Green Glide Triangle may be connected in a sideways motion before being locked in place with a downward motion. This means that pre-assembled corner installations with a return may be installed as one piece. Like the 300 Green Glide, the 310 Green Glide Triangle is designed for fast and accurate CAD/CNC in-shop layout, routing and cutout of both panels, and furring or mounting panels.

310 Green Glide Triangle also has a locking cap (sold separately) that snaps on to the back of the insert fastener. When used with the locking cap, the panels are very difficult to remove. They can also be used independently for high vibration areas with the addition of a locking cap. (315 Green Glide Triangle, Lock Cap)

Description

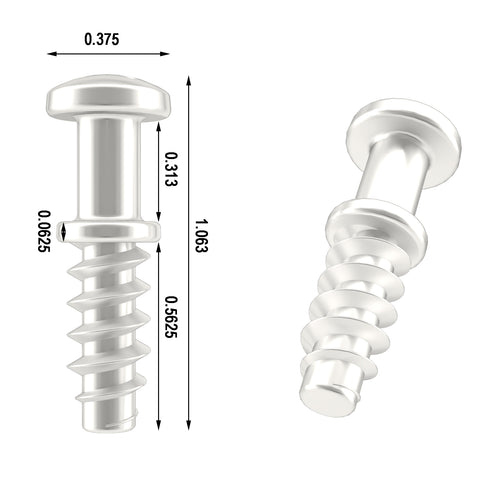

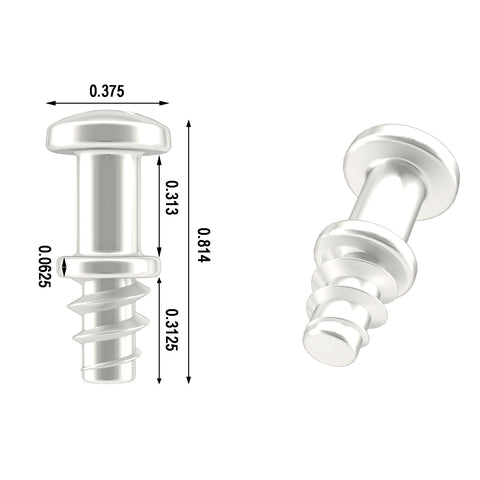

The advantage of the full CNC layout is that the double-headed screws can be set in a specific location on the panel. The mounting location can be pre-drilled, or quickly determined in the field with a drill template. The 310 Green Glide Triangle is faster, stronger and more precise than any other panel hanging system. The fastener is held firmly in place by compressing into a 1-1/2" x 1¼" routed pocket (½" deep). This elongated design, provides the keyhole length needed, for the steel mounting screw in the panel to glide and lock firmly in place.

Product Advantages

- The panel furring systems can be pre-engineered, which provides unparalleled control over exact panel locations.

- The insert can be hammered into place in seconds, and the panel then glides quickly and firmly into place on the mounting screws.

- Quickly disassembles for flat-pack shipping

- Using pre-engineered, large panel furring systems, greatly improves accuracy and efficiency.

- In the field, the furring system can be installed during the rough work period; later, panels may be installed with the finish work.

- If needed, the two stage install protects the panel work, and greatly reduces on-site hours during the most compressed phase of the project.

Cost Benefit, Estimates

Current estimates prove that the pre-engineered system saves about 1.5 hours per 36” x 96”, or about 10%. This system generally adds engineering hours, while saving substantial shop and installation hours. The hardware cost is similar to traditional clips.

Strength Testing with 3/4", with 45 lb. particleboard

TensileFailure (Horizontal pull) = 160 lbs. – Working Strength, Pull from Furring = 25 lbs.

ShearFailure (Vertical weight holding) = 330 lbs. – Working Strength, Weight holding = 50 lbs.

334 Euro Screws are Included with the 300 Green Glide

Other screws are In-Progress, please call to check availability.

- 335 Euro Screws, Cutoff to 5/16" Thread Length

- 336 Combination Screws, 1-1/2" Thread Length

- 238 Combination Screws, 9/16" Thread Length

- 238 Machine Thread, 10 -24, 9/16" Thread Length

More Information is Available Under "Video/Downloads"

Quick Introduction Animation:

Installation Guides:

Shop Demonstration Videos:

Drawings & Models:

SKU 310, Green Glide Triangle, 2D Drawing (pdf)

SKU 310, Green Glide Triangle, 2D Drawing (dwg)

SKU 310, Green Glide Triangle, 3D Model (dwg)

SKU 310, Green Glide Router 2 Template (dwg)

Share this item: