300 Green Glide | 5/16" Gap

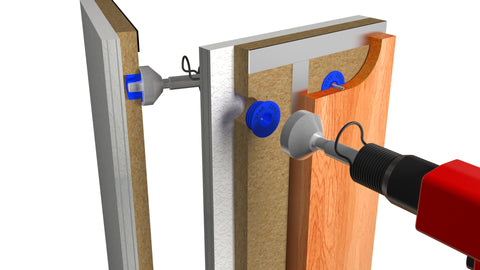

The 300 Green Glide is a key slot insert fastener designed to hang panels with precision, speed, and strength. This oval shaped compression fastener is 1-1/4” long x 5/8” wide and fits snug in a ½” deep hole. The key slot fits a 5/16” neck screw from the 300 Series (334 Mounting Euro Screw is included unless specified without screws). This fastener is hidden for optimal aesthetic and can withstand repeated removal without losing strength capacity.

The 300 Green Glide is best suited to pre-engineered (CNC cut) panel-furring systems. The 300 Green Glide gives the fabricator the ability to exactly control the placement of wood panels, ADA panels, fabric panels, artwork, graphics, upholstery and more. This insert fastener is ideal for panel-furring installations with complex, custom-shaped panels.

Read more ↓

- Product Description

- Introduction Animation

- Installation Guides

- Demonstration Videos

- Drawings & Models

- Product Specifications

DESCRIPTION

The 300 Green Glide is a key slot insert fastener designed to hang panels with precision, speed, and strength. This oval shaped compression fastener is 1-1/4” long x 5/8” wide and fits snug in a ½” deep hole. The key slot fits a 5/16” neck screw from the 300 Series (334 Mounting Euro Screw is included unless specified without screws). This fastener is hidden for optimal aesthetic and can withstand repeated removal without losing strength capacity.

The 300 Green Glide is best suited to pre-engineered (CNC cut) panel-furring systems. The 300 Green Glide gives the fabricator the ability to exactly control the placement of wood panels, ADA panels, fabric panels, artwork, graphics, upholstery and more. This insert fastener is ideal for panel-furring installations with complex, custom-shaped panels.

INSTALLATION

Prefabrication: The 300 Green Glide is designed for pre-engineered panel furring systems that have been laid out in CAD and cut on a CNC Router. This gives the fabricator the ability to exactly control the placement of wood panels.

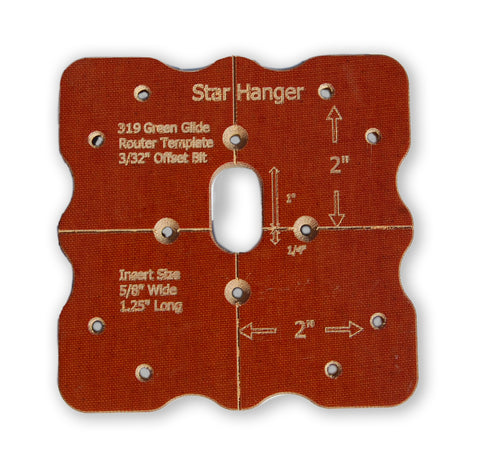

In Field: Star Hanger Systems has a selection of Templates, Router Bits, Alignment Pins, and Drill Bits available for simplified installation in the field. Please review Compatible Products and Tools at the bottom of this page.

SPECIFICATIONS

BENEFITS: Removable & Hidden, Fast & Easy field installation, Prefabricated Panel & Furring Systems pack flat for ideal shipping, allows for 1/16” expansion, minimized measuring with the 311 Alignment Pins.

SUGGESTED MATERIALS: Wood Panels ¾”, Acoustic Panels, Frames, Artwork, Trim, Plywood, Particle Board / MDF, Plastic, Solid Surface, etc.

FASTENER TYPE: Compression Fitted, Key Slot

DISTANCE FROM WALL TO PANEL: 1/16”-1/64”

REQUIRED REVEAL: 1/2”

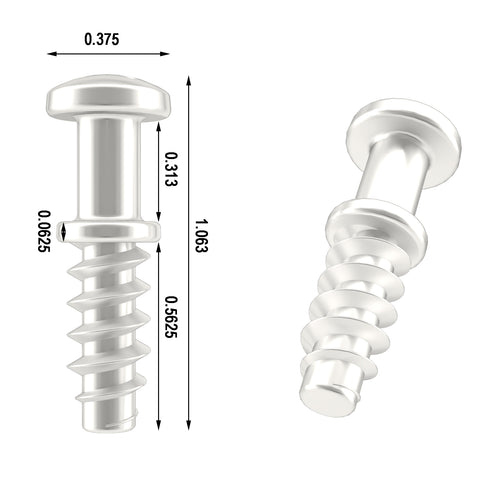

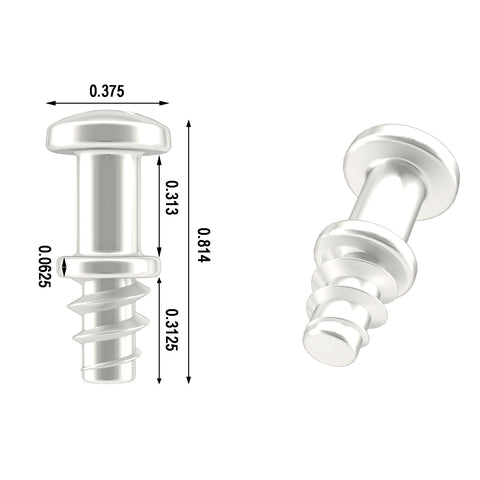

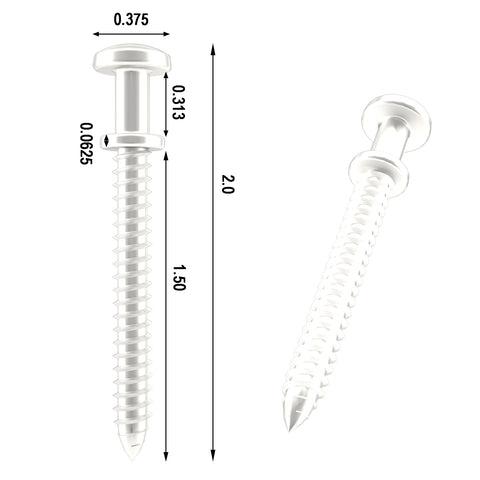

HOLE SIZE: Oval 1-1/4” H x 5/8” W x 1/2” D (CAD Drawings available at www.starhanger.com)

SPACING: Approx. 18”- 24” o.c. to prevent warping, templates have a 2” offset from all 4 corners.

MAXIMUM PANEL SIZE: 4’ x 12’

LOAD CAPACITY: Max 25lbs per connection point.

STOCK SIZE: Sold in packs of 10, 100, 1000, 5000 (334 Euro Screw is included unless specified “Without Screws”)

MATERIAL: High Impact, ABS Plastic | Dark Green Color

SCREW REQUIREMENTS: #10 Pan Head protruding 3/8” (Star Hanger Systems make a collection of screws with preset depths specified as 5/16” gap between a 1/16” permanent washer and the #10 Pan Head. These screws can be found in the 300 Series)

NOTE: Not recommended for overhead use.

TESTED STRENGTH RATING: With 3/4” 45lb Particle Board

• Tensile Failure (Horizontal pull)= 160lbs. Working Strength, Pull from Furring = 25 lbs.

• Shear Failure (Vertical weight)= 330 lbs. Working Strength, Weight holding = 50lbs.

334 Euro Screws are included with the 300 Green Glide unless specified

" No Screw"

Tools and Additional Screw Options Below

Quick Introduction Animation:

Installation Guides:

Shop Demonstration Videos:

Drawings & Models:

SKU 300, Green Glide, 2D Drawing (pdf)

SKU 300, Green Glide, 2D Drawing (dwg)

SKU 300, Green Glide, 3D Model (dwg)

Share this item: